NOTE: As the FIBERWOOD filament is produced using natural wood, which is part of its components, it is possible that there will be differences between the colour of the individual filament production series.

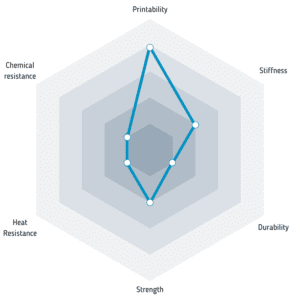

FiberWood properties:

- easy feeding of filament to the extruder – the material does not break

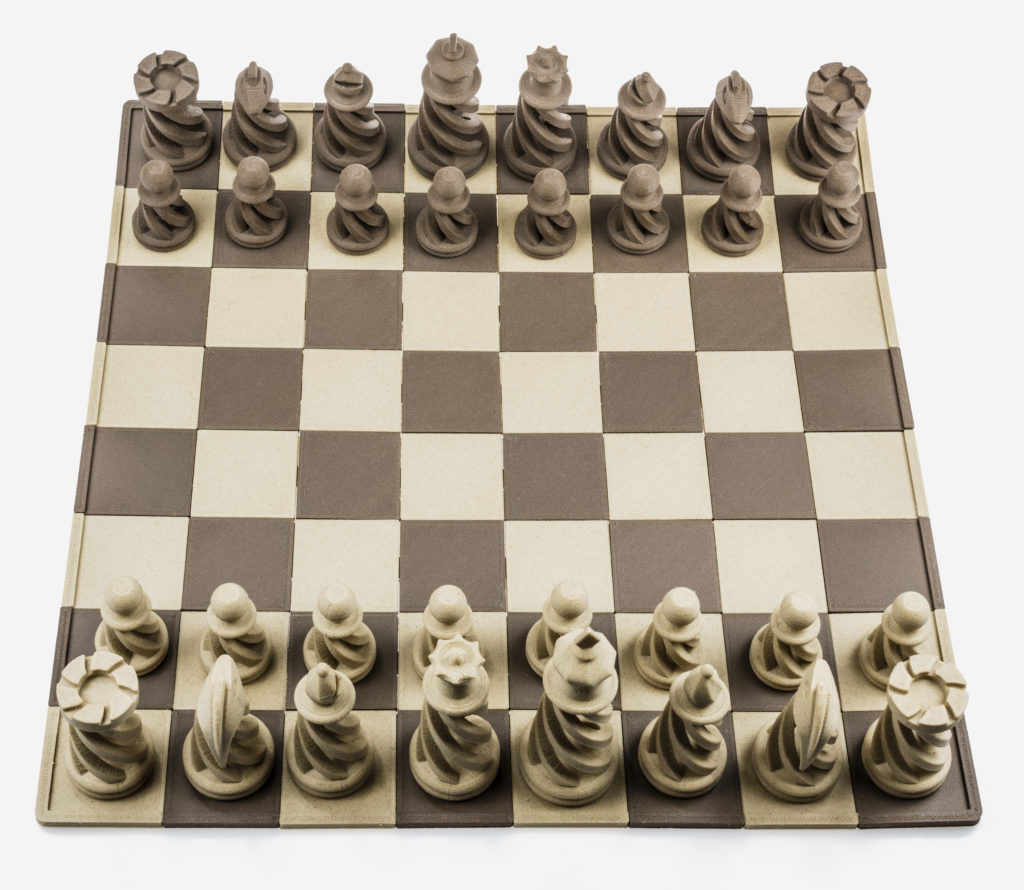

- possibility of grinding, polishing, varnishing and colouring the prints

How to print FiberWood?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 190-210°C |

| Bed Temperature | 50-70°C |

| Closed chamber | not required |

| Fan | 75-100% |

| Flowrate | 90-100% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 50°C / 4h |

| Notes | To avoid a situation where the nozzle gets clogged with wood particles, we recommend cleaning the extruder after each FiberWood print by using any type of PLA filament. Recommended minimum 0,5 mm nozzle |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

| 1.75 mm | +/- 0.02 mm | + 0.01 mm | 190-210°C | 50-70°C |

| 2.85 mm | +/- 0.02 mm | + 0.01 mm | 190-210°C | 50 -70°C |

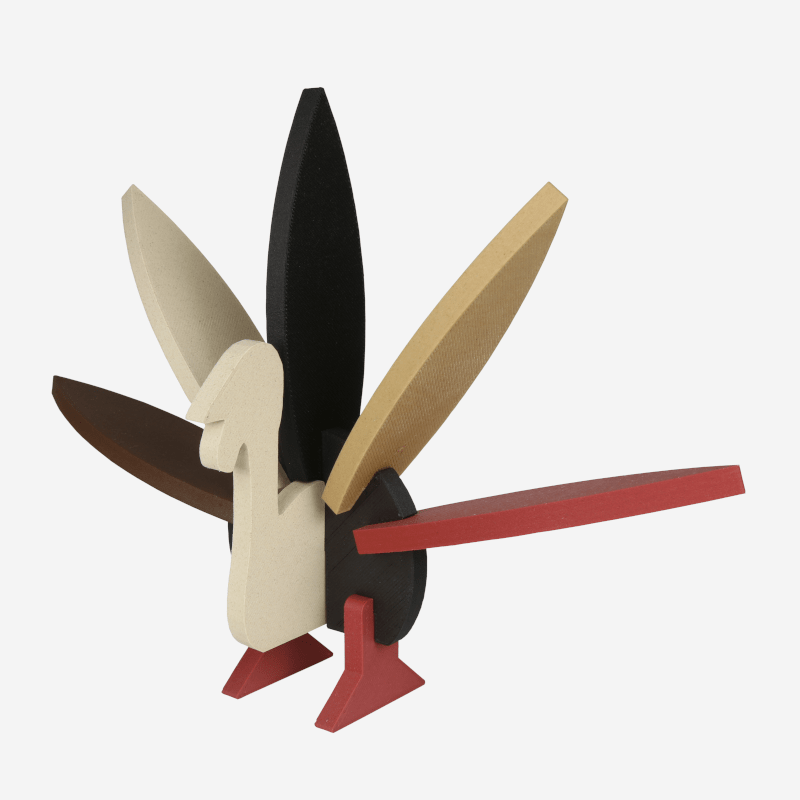

Colors: FIBERWOOD

Black

Brown

Carmine

Green

Natural

White