ABS PLUS properties:

- increased hardness and durability

- high impact resistance

- resistance to high temperature and abrasion

- possibility of machining and chemical treatment

- possibility of printing in open printers

How to print ABS PLUS?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | recommended |

| Fan | 0-10% |

| Flowrate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

| 1.75 mm | +/- 0.02 mm | + 0.01 mm | 250-270°C | 90-110°C |

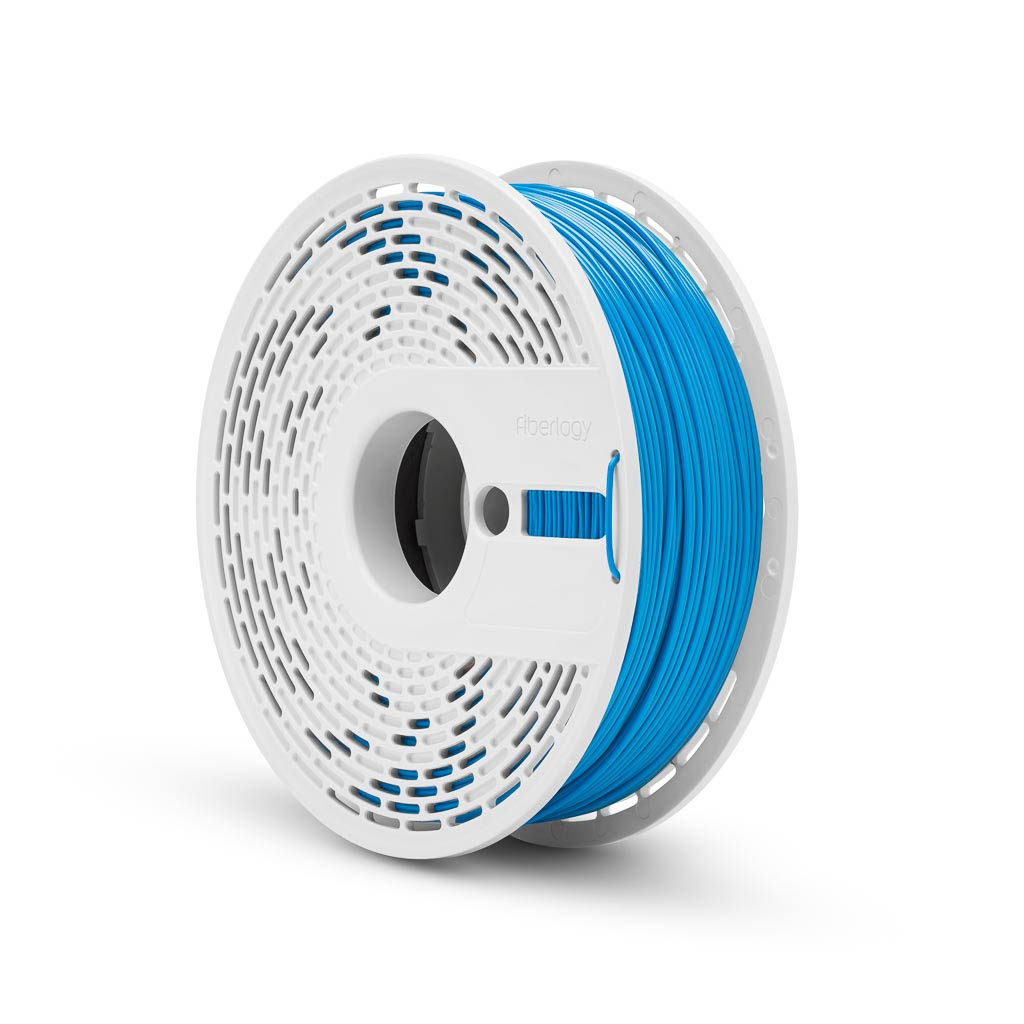

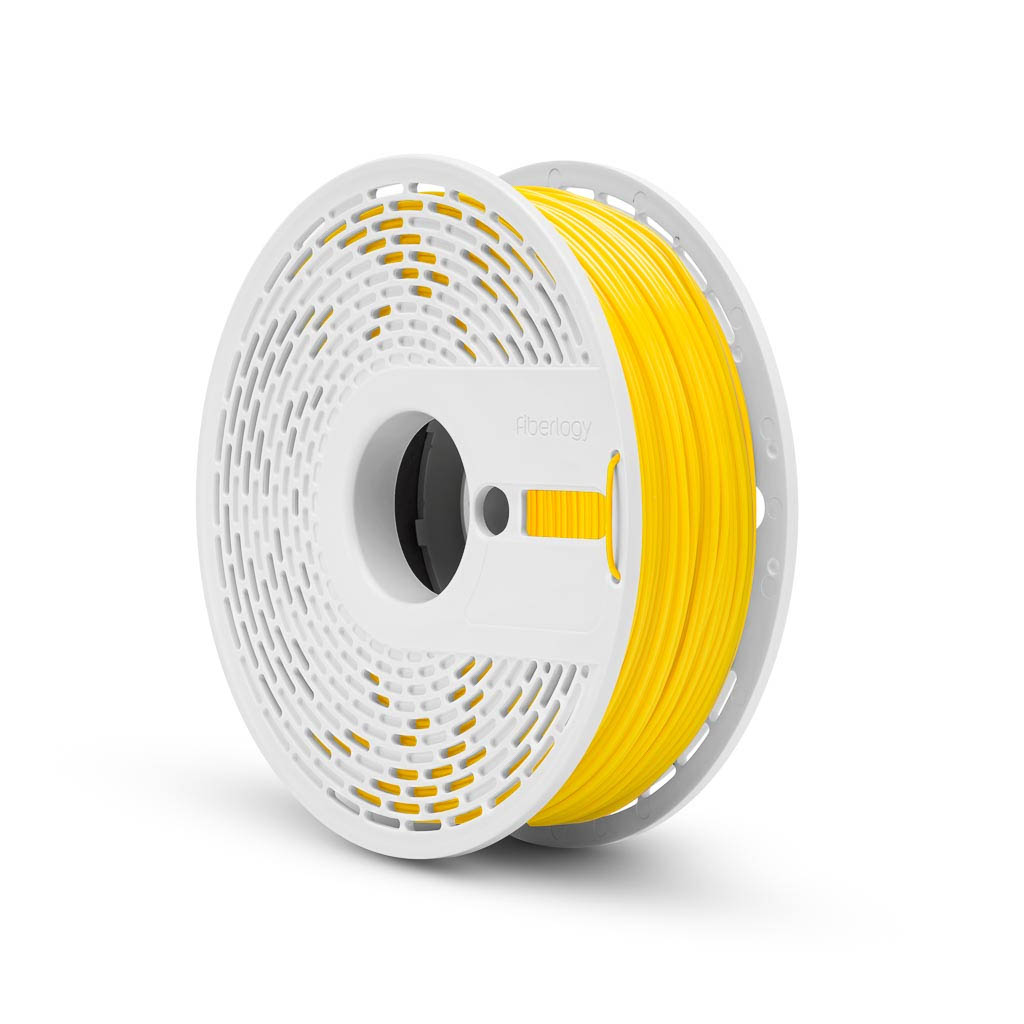

Colors: ABS PLUS

Black

Blue

Red

Yellow

Graphite

Gray

White