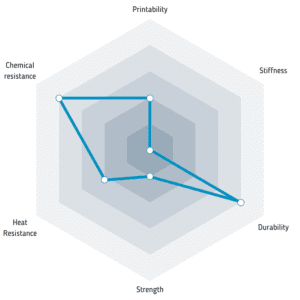

FiberFlex 30D properties:

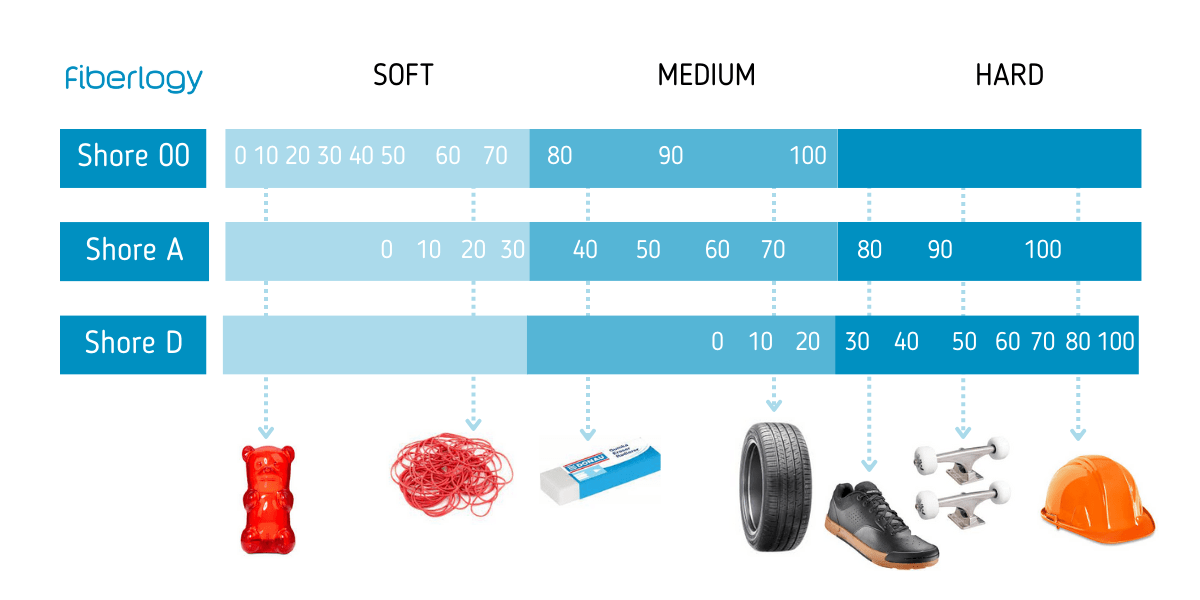

- 30D Shore hardness

- high impact resistance in low temperatures

- very good thermal, chemical and abrasion resistance

How to print FiberFlex 30D?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 200-220°C |

| Bed Temperature | 50-70°C |

| Closed chamber | not required |

| Fan | 50-75% |

| Flowrate | 105-110% |

| Printing Speed | < 35 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 1-2 mm |

| Retraction Speed | 10-30 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | To remove the print easier, it is recommended to heat the bed to 110°C |

Fiberlogy FiberFlex 30D has been positively assessed in the Open Filament Program (OFP) project run by Raise3D:

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

| 1.75 mm | +/- 0.05 mm | + 0.03 mm | 200-220°C | 50-70°C |

Colors: FIBERFLEX 30D

Black

Light Green

Blue

Pink

Red

Orange

Yellow

Beige

Graphite

Gray

White