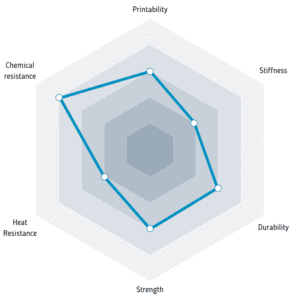

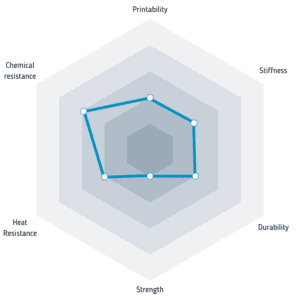

ESD ABS properties:

- high resistance to electrostatic discharge and chemicals

- high impact strength

- resistance to high temperatures and scratching

- possibility of mechanical and chemical processing

How to print ESD ABS?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-265°C |

| Bed Temperature | 90-110°C |

| Closed chamber | recommended |

| Fan | 0-10% |

| Flowrate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the presence of nanoparticles, the filament structure is not smooth. The presence of thickening is natural, but it does not affect the correct diameter of the filament, which is within the declared range. Due to the possibility of accumulation of nanoparticles, we recommend using a 0.6 mm nozzle, and if the nozzle clogs, the printing temperature should be increased. |

| Diameter | Diameter tol | Oval tol | Printing temp | Table temp |

|---|---|---|---|---|

| 1.75 mm | +/- 0.02 mm | + 0.01 mm | 250 -265°C | 90-110°C |

Colors: ESD ABS

Black